SharkGrip Coatings

Fast Fleck - Accelerator

Fast Fleck Users: Leave a quick review and we’ll send you store credit.

Use code FLECK10 for 10% off your next Fast Fleck order.

- SKU:

- FF-1

- MPN:

- FF-1

- Condition:

- New

- Availability:

- Usually Ships Sames Day

- Weight:

- 11.00 LBS

- Width:

- 6.50 (in)

- Height:

- 10.50 (in)

- Depth:

- 4.00 (in)

Frequently bought together:

Description

FAST FLECK ACCELERATOR™

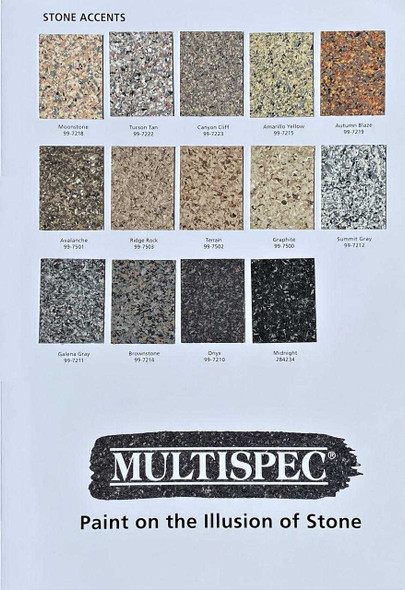

Moisture Scavenger + Particle Control Additive for MULTISPEC® Multi-Color Fleck

Same-Day Workflow

Faster Dry-to-Sand

Flatter Laydown

Professional-use additive for faster MULTISPEC® fleck workflows.

Purpose

Fast Fleck Accelerator™ reduces the dry-to-sand bottleneck in water-based MULTISPEC® fleck systems used for countertop refinishing. It promotes true through-dry, improves particle laydown, and helps enable same-day nib knockdown and clear-coating under typical shop conditions.

(What It Delivers)

- Faster dry-to-sand time for water-based fleck (same-day workflow)

- Reduced nibs & texture for a smoother surface before clear

- Improved fleck presentation (bigger, more aesthetic appearance; easier vertical application)

- Lower clearcoat consumption due to flatter fleck laydown

- Improved cleanability by minimizing micro-peaks that can shear under use

Field Advantage: Less texture to bury = fewer coats of clear to chase flatness and gloss.

(Problems It Prevents)

- Overnight wait times just to sand (lost production time)

- Texture telegraphing through clear if you skip sanding

- Micro-nibs protruding into the clear that can shear later under countertop use

- Uneven clear build needed to bury texture (inconsistent gloss/DOI over time)

- Reduced sanitation due to micro-voids and contaminant hold points

Bottom line: Faster, flatter, cleaner results without gimmicks.

Mix Ratio & Mixing Instructions

Recommended ratio: 2/3 MULTISPEC® Fleck: 1/3 Fast Fleck Accelerator™

- Combine in spray cup (or mixing container) at the recommended ratio.

- Stir 2–3 minutes. It may look “over-watered” at first.

- Keep stirring: within 1–2 minutes it re-homogenizes and comes together.

- Don’t shortcut mixing time—full contact across all fleck is critical.

Spray Setup (Starting Point)

- Tip size: 2.0 mm minimum (or larger as needed)

- Air to gun: lowest possible while maintaining consistent pattern

- Fluid control: ~2/3 open as a starting point

- Technique: do not “pound” the fleck—apply light, even coats for controlled laydown

Finish tip: Light, even passes help the particles lay flatter, which reduces the clear you’ll need later.

Between-Coat Air Drying

Air volume is more effective than concentrated heat. High airflow evacuates the humidity boundary layer and promotes uniform evaporation without skinning.

- Pop the gun off the turbine and allow air drying a few minutes between coats.

- Use turbine airflow or a high-volume blower at a safe distance (don’t disturb the pattern).

- Repeat coats until 100% coverage is achieved.

Nib Knockdown (How to Sand)

Goal: remove micro-nibs and texture peaks without cutting through the fleck layer.

- Allow fleck to reach the sandable window (see temperature guide below).

- Use a light square fine foam sanding pad (e.g., 3M fine foam) with very light pressure.

- Make a quick, uniform pass to knock nibs down (do not overwork the surface).

- Blow off thoroughly and tack cloth before clearing.

Pro Tip: Confirm sandability on a small test area before full knockdown + clear.

Professional Notes

- Designed for professional workflows and consistent shop practices.

- Air volume > heat: airflow is the most reliable way to shorten the dry-to-sand window without skinning.

- Always verify sandability on a small test area before full nib knockdown and clear.

- Cleaner clearcoat results: flatter fleck helps produce more consistent gloss and DOI over time.

Stop Waiting Overnight — Go Same-Day on MULTISPEC® Fleck

Built for countertop refinishers who want faster production, flatter fleck, and cleaner clears without gimmicks.

▶ View Fast Fleck Accelerator™ on EAHIndustrial.com video coming soon

Dry Time Reality Check (Read This)

Dry-to-sand time is not a fixed number—it’s a result of how you spray and your shop conditions. Fast Fleck Accelerator™ can shorten the window dramatically, but final dry time will depend on:

- Application technique: Don’t “pound” the fleck on. Heavy wet coats trap moisture and extend dry time. Light, even passes lay flatter and dry faster.

- Coverage style: 100% coverage takes longer than light flecking. More material = more water that must leave the film.

- Airflow beats heat: High air volume removes the humidity boundary layer and speeds uniform evaporation. Concentrated heat can skin the surface and slow true through-dry.

- Temperature & humidity: Cool temps and high humidity extend the window—plan for more airflow and more time.

- Mix ratio discipline: Stay consistent. Over-diluting or “eyeballing” ratios changes laydown, flash, and sand-ability.

- Film build & surface type: Porous or cold substrates can hold moisture and slow the dry-to-sand point.

Pro Rule: Always test sand-ability on a small area before full nib knockdown and clearing.