SharkGrip Bathtub Refinishing Coatings

High Solids High Build Epoxy Primer

- SKU:

- SG1P

- MPN:

- SG1P

- Availability:

- Usually ships Same Day

- Weight:

- 22.00 LBS

- Width:

- 18.00 (in)

- Height:

- 14.00 (in)

- Depth:

- 19.00 (in)

Description

SHARKGRIP EPOXY HIGH BUILD PRIMER

Modified Epoxy Primer — Flat-Drying, High-Solids, High-Fill

This is the primer version of our SharkGrip Modified Epoxy system — engineered to dry flat like a true primer while delivering serious build and a smooth, stable base for topcoats. Built for tubs, tile, counters, and commercial refinishing where you don’t get a second chance.

Built for the Realities of Tub, Tile & Countertop Prep

The best finish starts with the best base. SharkGrip Epoxy High Build Primer is designed to fill, level, and stabilize surfaces so your topcoat looks cleaner, lays flatter, and lasts longer. It’s a workhorse primer for the bathtub, tile, and countertop refinishing industry where speed matters — but failure costs more.

The Great Attribute: BUILD

This primer is known for its high build. It helps mask minor imperfections that would otherwise require extra bodywork time. When you need a cleaner surface fast, build is the advantage.

Flat-Drying Primer Surface

This is the same epoxy platform as our High Gloss Epoxy Topcoat, but the primer version includes a flattening package so it dries flat like a true primer and lays down as a stable base coat.

Where Pros Use It

- Bathtubs (steel, cast iron, fiberglass) — as a true build primer base

- Tile walls, surrounds, and shower areas requiring a stable primed foundation

- Countertops (laminate, cultured marble, composites) prior to epoxy/urethane topcoats

- Any refinishing surface where a high-build primer is needed to smooth minor defects

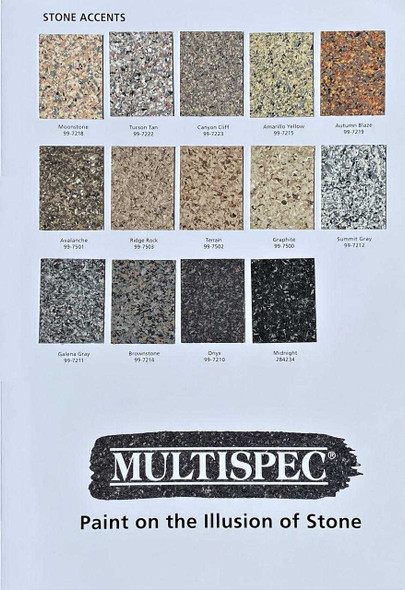

A Perfect “Canvas Coat” for Multispec

This primer makes an excellent base coat canvas for Multispec. We can tint it any color, which helps you build the exact stone-tone foundation you want before applying your effect layers.

Same Proven Epoxy Platform — Now as a Primer

The Part A backbone remains the same epoxy platform you already trust in SharkGrip High Gloss Epoxy. The primer version uses a flattening system so the film dries flat, builds better, and supports a cleaner topcoat result. It maintains the same immersion-service mindset and can be purchased in any color.

Build the Base. Prevent Telegraphing. Make Gloss Look Expensive.

SharkGrip Epoxy High Build Primer is the foundation coat that saves time, smooths minor defects, and helps your topcoat look flatter, deeper, and more professional — without relying on automotive-style sanding steps.

Additional Information

Select COLOR and COMPONENT combination below: |

IF ORDERING PART " B " ONLY - Select " NO COLOR |

SHARKGRIP

EPOXY REDUCER

(Epoxy Thinner)

Premium reducer engineered for SharkGrip High Gloss Epoxy Topcoat and our High Solids High Build Epoxy Primer — two systems built in the ~82% solids class.