SharkGrip Bathtub Refinishing Coatings

Melt Down Urethane Paint Repair Blender

- SKU:

- MD-16

- MPN:

- MD-16

- Condition:

- New

- Availability:

- Usually Ships the same day

- Weight:

- 3.00 LBS

- Width:

- 2.50 (in)

- Height:

- 8.00 (in)

- Depth:

- 2.50 (in)

Frequently bought together:

Description

Melt Down works by temporarily reducing the effective solid content at the perimeter of the repair while keeping the resin system chemically active. That softens and re-wets the dry edge and creates a controlled transparency gradient, so the repair edge visually disappears.

In automotive terms, this is “burning the halo” but tuned for professional refinishing coatings.

In automotive terms, this is “burning the halo” but tuned for professional refinishing coatings.

What Melt Down™ Does

- Re-wets and softens the dry edge of existing coatings

- Optically reduces pigment density at the perimeter (edge fade)

- Extends and levels the blend zone for a cleaner transition

- Maintains compatibility with SharkGrip coating systems

Primary Use: Chip Repair & Spot Blending

For consistent, repeatable repairs, keep these essentials on your truck or in your shop.

Step-By-Step: Chip Repair & Spot Blend

- Shake your cans aggressively.

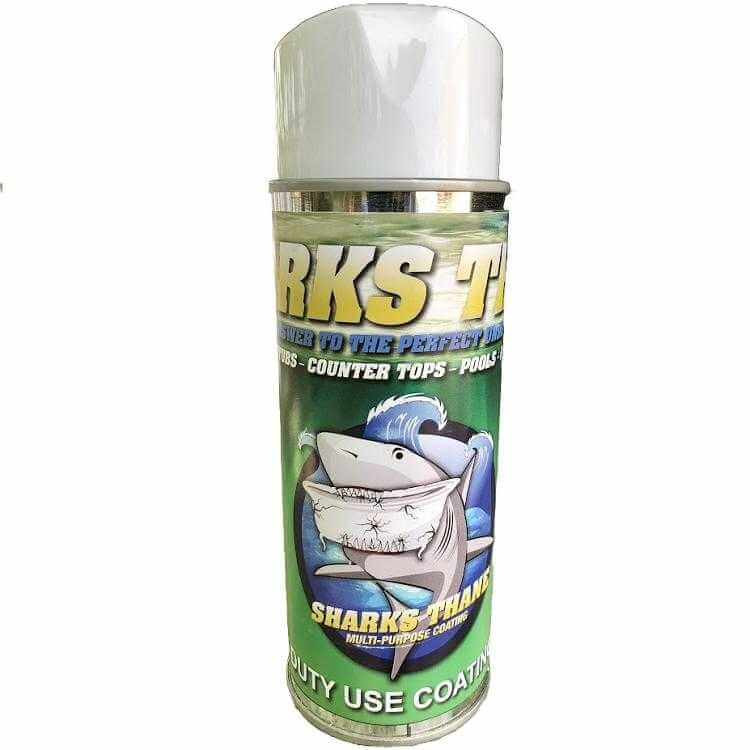

Shake SharkThane Quick Dry spray cans vigorously before use. Spray a few test shots first to confirm clean atomization and consistent flow. - Complete chip repair / body work first.

Fill, shape, sand, and inspect. The repair must be flat and correct before you spray. - Mist Power Bond.

Lightly mist Power Bond Dual Silane Coupling Agent over the repair area. Let dry completely—this chemically unifies filler, old coatings, and substrate. - Tack cloth the area.

Remove all lint, dust, and residue. - Pepper Spray coat with SharkThane.

From a distance, mist in thin passes and build coverage slowly. Do not try to cover in one coat. - Blend using Melt Down™.

Mist Melt Down across the repaired area and outward using light, controlled passes. Wait about 60 seconds between passes. This is where the halo disappears.

CRITICAL RULE

Do not tape hard lines. Never mask a perfect square around a chip. Hard lines create visible blend borders.

Pro-Level Use:

Full Tub - MELT-DOWN

Spray all build coats and hide coats on a full tub, tile, or countertop. Then, prior to applying your “Final Gloss Coat”

STOP

STOP! Don’t spray your final gloss coat yet.

Follow the next steps and you’ll lay down a finish that looks like a base coat / clear coat system— the kind of gloss normally associated with high-end paint work. This is how you win the room on a demonstration job—especially when you’re proving yourself for a large hotel project bid.

Why this step is a competitive advantage

- Reflows the surface to help eliminate dry-spray texture and stop/start marks

- Amplifies depth and DOI (Distinctness of Image) for that “wet glass” look

- Smooths microscopic texture so the finish reads cleaner under bright light

- Levels the final appearance so the whole job looks intentionally “premium”

Bottom line: When a property manager, GC, or hotel decision-maker sees that finish, they don’t compare you to the average refinisher they compare you to a top-tier finisher.

Spray all your build coat and hide coats on a full tub, tile, or counter, and prior to applying your " Final Gloss Coat " Stop and follow these next steps for the most amazing final finish. It will resemble a base coat; clear coat application normally associated with high end paint jobs.

- Open Quart bottle of Melt Down Add 1–2 ounces of Melt Down™ into your spray cup. (Add to your existing mix)

- Mix thoroughly.

- Turn the fluid output down to prevent runs and sags as ( you just added more solvent.

- Spray one thin even wet gloss coat over the entire surface.

This final coat:

- Reflows the entire surface

- Eliminates dry spray and stop-start marks

- Softens microscopic texture

- Slightly increases transparency for depth

- Amplifies DOI (Distinctness of Image)

Pro Tips (Read This)

- Always adjust fluid when adding Melt Down™ (viscosity changes fast).

- Temperature matters: blending lives in a narrow timing window—don’t rush passes.

- On larger areas, use Melt Down™ as a final blend coat to eliminate striping and dry edges.

- Melt Down is not a paint or reducer. It’s a controlled optical blending tool.

EAH — The Spray Equipment Authority

You can buy products anywhere. But when you’re doing professional repair blending, the difference is process + compatibility + support. If you want chip repairs that disappear and gloss that looks sprayed—not patched—EAH has the system.

2 Reviews

-

Melt Down Urethane Paint repair blender

This stuff is a must for your repair kits. Blends so much better than the 80% reducer / 20% top coat. The blending of the halo is a game changer.

-

Meltdown Repair Blender

I do a ton of chip repairs for contractors on new builds. This stuff truly makes the repair seamless. Zero halo. As long ad you color match correctly it's impossible to tell where the repair was done. I've used a few other blenders and they're ok. I can make them work. But this makes the job so much easier. Thanks!