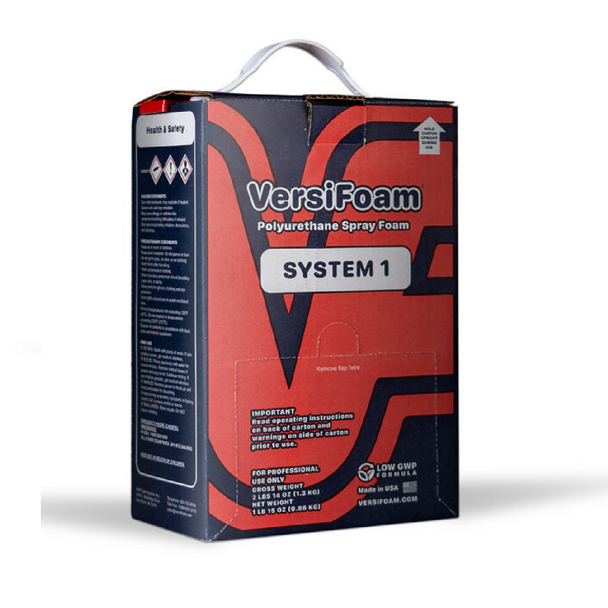

Versi-Foam

VFS1 Versi-Foam Kit (Small)

- SKU:

- VFS1

- MPN:

- VFS1

- Condition:

- New

- Availability:

- Usually Ships within 24 Hours

- Weight:

- 3.00 LBS

- Width:

- 10.00 (in)

- Height:

- 4.00 (in)

- Depth:

- 6.50 (in)

Frequently bought together:

2 Reviews

-

100% Recommended!!

Verdi-Foam is the best foam that I ever have used. It made the job so easy. Definitely, I will continue using it. Thanks E.A.H. Industrial for great products.

-

Versi foam

Great! Easy to use. Provides excellent support for voids under tubs and showers